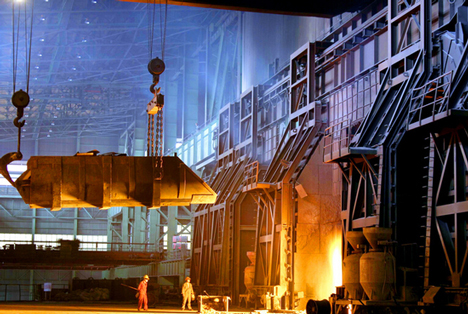

In order to implement the long-term strategic development plan, shape a modern steel base, produce high-quality and high value-added products, in order to improve the automation level of converter steelmaking, shorten the converter production cycle, and improve the double hit rate at the end of converter blowing, Liuzhou Iron and Steel Group is ready to transform the original 3×40t converter, build two 150t converters, and set up two sets of sublance equipment and automatic steelmaking system at the same time.

The converter sublance systems and metallurgical model (including static and dynamic control model) provided by our company have advanced, mature and reliable production technology of converter sublance and automatic steelmaking system, and have design, manufacturing, installation, commissioning, production, operation and maintenance of specialized technical personnel and sophisticated processing and manufacturing equipment, and have an effective management system and good performance for the project.

Since Liugang 7# and 8# converters have been equipped with sublance systems and steelmaking models, the production cost has been greatly reduced, the product quality has been improved, and the level of automated steelmaking has been improved.